Product

Product quality and flight safety

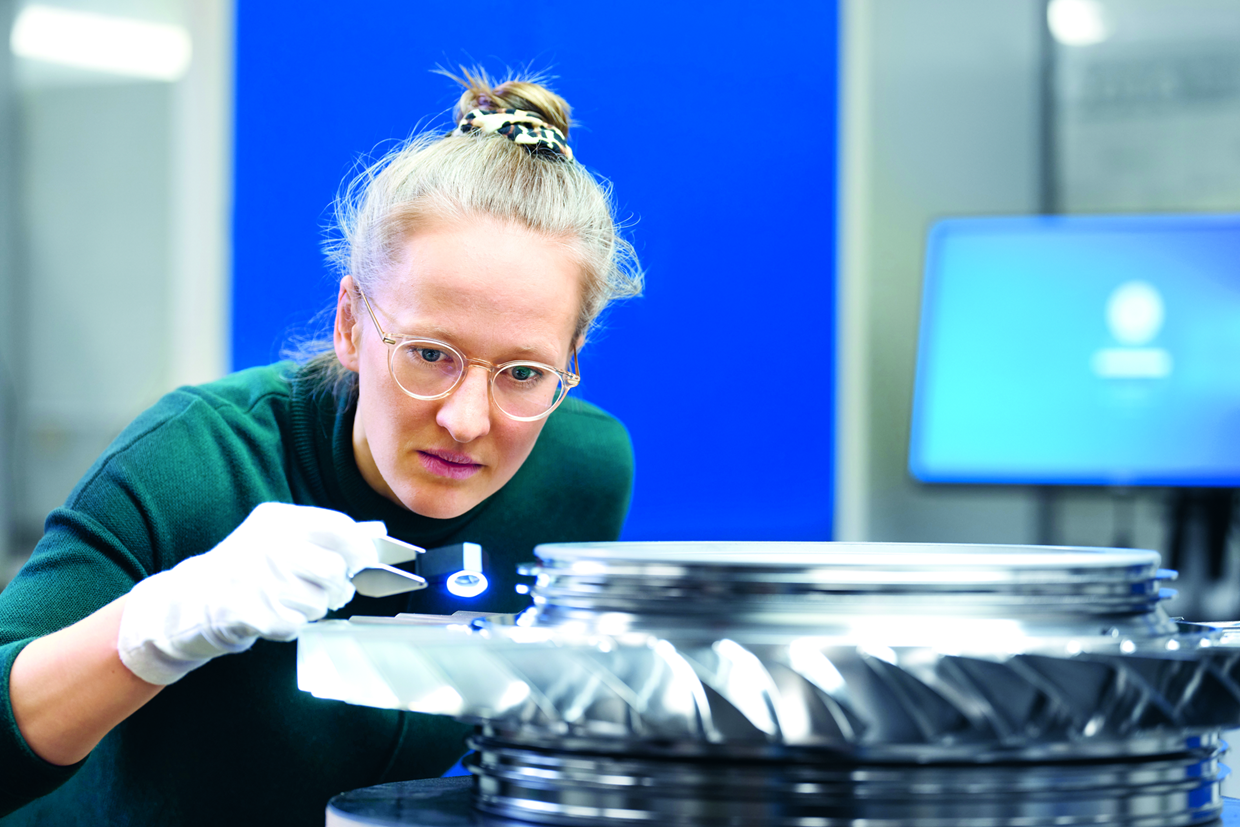

Safety first—for us, safe flight operation is way more than just a legal requirement. In aviation, it is the highest priority, period. That’s why we place high demands on safety and quality—for reliable and high-quality products made by MTU.

Product quality and flight safety are very important to MTU. High quality together with product safety and reliability are enshrined in the MTU Principles as key corporate objectives. MTU’s quality vision for 2025 also aims at error-free quality and product safety in flight, as well as high customer satisfaction. Our vision is Zero Defects; in this, we stand for sustainable quality management.

A high level of product quality and safety is crucial for customer satisfaction and our competitiveness. “We increase the satisfaction of our stakeholders” is therefore one of our overarching corporate objectives. The secondary objectives for 2023 were defined in more concrete terms, with the aim of underscoring MTU’s attractiveness as a partner through the high performance and quality of its products and services.

A model management system for quality

Conditions in the aviation industry are strictly regulated, and the company must comply with the legal requirements imposed upon it as an organization that develops, manufactures, and maintains products, parts, and equipment for the aviation industry. A Group-wide integrated management system (IMS) ensures compliance with laws and internal regulations and clearly assigns responsibilities within the company. One principle of the IMS policy is that “safety takes priority in what we do.” The quality framework is enshrined in a management manual that is binding for all employees and managers across the Group. The company’s dedicated quality department, Corporate Quality, is directly subordinate to Executive Board member Dr. Silke Maurer, Chief Operating Officer (COO), and reports quarterly to the full Executive Board on quality aspects and flight-related incidents. MTU Safety Management in accordance with the International Civil Aviation Organization (ICAO) standard is part of the IMS and defines how to handle safety-related incidents in MTU facilities and in air traffic. Appropriate organizational structures and responsibilities, such as a Flight Safety Board and a Flight Safety Manager, have also been established.

IMS, our certified integrated management system, supports us in ensuring customer satisfaction, process orientation, and continuous improvement in all phases of development, production, and maintenance. IMS takes into account, for example, the requirements of the standards ISO 9001, EN/AS9100, ISO 14001/EMAS, and ISO 45001, and serves as a model approach in the aviation industry.

And complying with legal requirements concerning safety is subject to strict monitoring by the relevant authorities. These include aviation-authority licenses, approvals, and certifications as well as safety and environmental requirements as legally mandated by regulatory authorities. Through stringent quality standards, we ensure that these are implemented across the Group and at all levels of the value chain in accordance with the law. We have customers and authorities conduct regular internal and external audits of quality issues to ensure that the uniformly high standards within the company comply with regulatory requirements.

Safety throughout the lifecycle

We examine our engine modules for their impact on the environment, health, and safety throughout their development, production, and operation lifecycles. Accordingly, we cover all major stages of a product’s service life. The key to continuous progress is the development phase. We take into account all safety and environmental requirements of regulatory authorities in the early stages of developing new engines for later use, and compliance must be documented as part of the certification process. We employ a comprehensive testing program involving test rigs and test series to validate the safe flight operation of our products. This includes being able to ensure safe operation during a hailstorm or a bird strike (following a bird ingestion event) and complying with strict limits on pollutants and noise emissions. MTU components frequently exceed aviation authority requirements, because our customers demand high standards when it comes to fail-safe operation and eco-efficiency.

We use only fault-free and clearly identified components that have been approved by the appropriate aviation authority, are based on approved development documentation, and have been produced or maintained in compliance with aviation regulatory processes by a company officially authorized to do so.

The aviation sector has strict rules governing documentation in order to verify the airworthiness of components and engines. There must be no gaps in documentation for the product’s entire service life. We hold our suppliers to the same standards and audit them regularly to ensure compliance. To ensure quality and safety requirements are upheld, we have implemented comprehensive monitoring and testing processes along the entire value chain. Safety-critical components (engine components are categorized into various safety classes) are subjected to particularly rigorous testing to verify their technical quality. Strict requirements also apply to materials. Since fail-safe materials are a basic prerequisite for aviation safety, all engine components, including all materials we use, must be approved by the aviation authorities after undergoing extensive test series.

The reporting year again saw a positive result in that there were no breaches of statutory regulations regarding compliance in connection with the purchase or operation of our products that resulted in a fine, sanction or warning for MTU.

Continuous monitoring of quality

We set great store by customer complaints as an indicator of our customers’ satisfaction with the quality of MTU products. We follow up and analyze all customer complaints submitted to us relating to products delivered in substandard quality. Appropriate measures are then defined and implemented so as to permanently eliminate the cause of the defects. Success of these measures is closely monitored. Customer complaints are assessed at the site level. At most of our sites, the number of customer complaints fell or remained constant in the reporting year.

Geared turbofan fleet management plan

In the course of 2023, it emerged that the service life of components in the share handled by program partner Pratt & Whitney may be limited under certain circumstances. The reason for this is a rare condition of the powder metal used in the production process. As a result, there was a need for a comprehensive inspection program for PW1100G-JM geared turbofan engines. In the coming years, an additional 600 to 700 shop visits will be necessary to inspect the relevant components and replace them if necessary as a preventive measure.

Further development of safety management system underway

At MTU, we develop and refine our quality system together with our standards and regulations on an ongoing basis. This involves applying the ideas that emerge, for example, from collaboration in the Aero Engine Supplier Quality Group (AESQ) or from regular exchanges of experience and information among our quality managers in the aviation industry. Continuous development primarily concerns MTU’s body of rules and regulations and its internal quality reporting system.

We include all our employees in our high quality standards: managers and employees receive site-specific training on quality issues, and all employees receive IMS training. In addition, we are committed to a positive no-blame culture at MTU, characterized by openness and collaboration, and raise awareness about and provide ongoing training on this subject.

In the reporting year, MTU began further developing its safety management system in light of new regulatory requirements from the European aviation authority. A new training concept with mandatory online training for all employees and in-depth training for MTU safety personnel was rolled out for the German sites as a first step. In addition, Quality Day 2023 was dedicated to the topic of flight safety and the safety management system as part of the Passion for Quality initiative. The implementation of the new industry-wide AS13100 standard, which was jointly developed in the AESQ, also made further progress in 2023. This standard must be incorporated into MTU’s body of rules and regulations and find practical application with MTU and its suppliers. MTU is also working on a new edition of the standard, which will incorporate initial lessons learned.