Production & maintenance

Conservation of resources

We use resources responsibly. That includes the use of primary resources, a high degree of material efficiency, and the careful handling of water, in addition to waste management and recycling. Our environmental management goals include low resource consumption and a circular approach for products and processes insofar as possible.

MTU is reliant upon raw materials for manufacturing and maintenance at its facilities. In addition to the use of renewable and non-renewable energy, there is also the use of water and the consumption of various materials. Our environmental management system at our sites controls our demand for and use of raw materials with the aim of obtaining high levels of efficiency in manufacturing and maintenance. This means low resource consumption and a circular approach for products and processes insofar as possible. We have set out the responsible use of resources as a guideline for all employees in our Code of Conduct and our MTU Principles. The efficient and sustainable use of natural resources such as water, energy, and raw materials as well as the avoidance or minimization of risks to human rights are defined as environmental due diligence obligations for the protection of human rights in our Policy Statement on the Protection of Human Rights and comply with the requirements of Germany’s Act on Corporate Due Diligence Obligations in Supply Chains.

MTU employees are committed to the environment

Volunteers from MTU Maintenance Canada cleaned up the shoreline along the Boundary Bay Dyke Trail in Delta, British Columbia. In 2023, MTU volunteers also took part in Rama Dama, the spring clean-up of the Karlsfeld community adjacent to MTU’s headquarters in Munich. In a forest initiative organized by MTU Aero Engines Polska, employees cleared the forest of garbage and planted trees. The MTU Maintenance Serbia management team collected waste on the Tara River during a visit to one of the nature reserves in western Serbia. (clockwise)

Water management

We use water responsibly as a natural resource, and we have set up a local water management system for water protection at the production and maintenance sites. In keeping with the precautionary principle, we treat wastewater properly and in accordance with the applicable legal requirements. Our water consumption depends on production and maintenance volumes. Targets for the protection of the resource are formulated at the local level.

Our fully consolidated production and maintenance sites are situated in Germany, Poland, Serbia, and Canada, none of which are water-stressed regions as determined by the World Resources Institute’s Aqueduct Water Risk Atlas (water risk for those countries: low or low/medium). Water-stressed regions are regions in which water is a scarce resource. We monitor the development of water availability in the regions in which we operate, which allows us to make decisions about additional measures to take, if required.

Our water consumption

We use drinking water for production and maintenance processes, in sanitary facilities, and in company restaurants. At the Munich site, we also use well water for cooling processes in machinery. As a result of higher capacity utilization, water withdrawal in the reporting year amounted to 9.1 million m3 (2022: 8.5 million m3). We use large amounts of Quaternary groundwater from our own wells for cooling at the Munich site. In other words, the water used by the MTU Group in 2023 was 98% groundwater and only 2% came from the municipal drinking water supply. Using well water contributes to environmental protection and climate action, as it eliminates the need for energy-intensive cooling processes such as compressor cooling systems. MTU is required by the authorities to constantly release a small amount of well water into the Schwabenbächl river near the site. This water is regularly tested for pollution to ensure stable conditions for the river’s wildlife.

We use recirculated water as much as possible in chemical process baths for applying protective coatings to blades and also for the process water in installations for testing component damage. Thanks to this recirculation, we have to treat only a small amount of wastewater before discharging it into the municipal sewers. We also use recycled water for the chemical cleaning of engine parts. Our sustainable water management also includes systematic inspection and renovation of the well water and sewer networks.

|

Water withdrawal (in 1,000 m 3 ) GRI 303-3 |

||||

|

|

|

2023 |

2022 |

2021 |

|

|

Total |

9,095.4 |

8,538.5 |

8,079.6 |

|

Withdrawal |

Municipal water |

184.6 |

183.4 |

159.9 |

|

|

Groundwater |

8,910.8 |

8,355.1 |

7,919.7 |

No water abstraction in water-stressed regions; KPIs on water recycling and consumption in accordance with GRI 303-4 and 303-5 are shown in the Notes.

Water quality

We treat wastewater in suitable sewage systems according to the type and extent of pollution. After treatment, the quality of the discharged wastewater complies with the official requirements for the respective sites. We carry out strict monitoring at the sites to ensure that legal limits are observed and comply with all local authority requirements. Neither water sources nor water surfaces were negatively impacted or polluted by our operating activities. This applies in particular to our site in Canada, which is situated in direct proximity to the ocean.

Jump start for more biodiversity

Circular economy

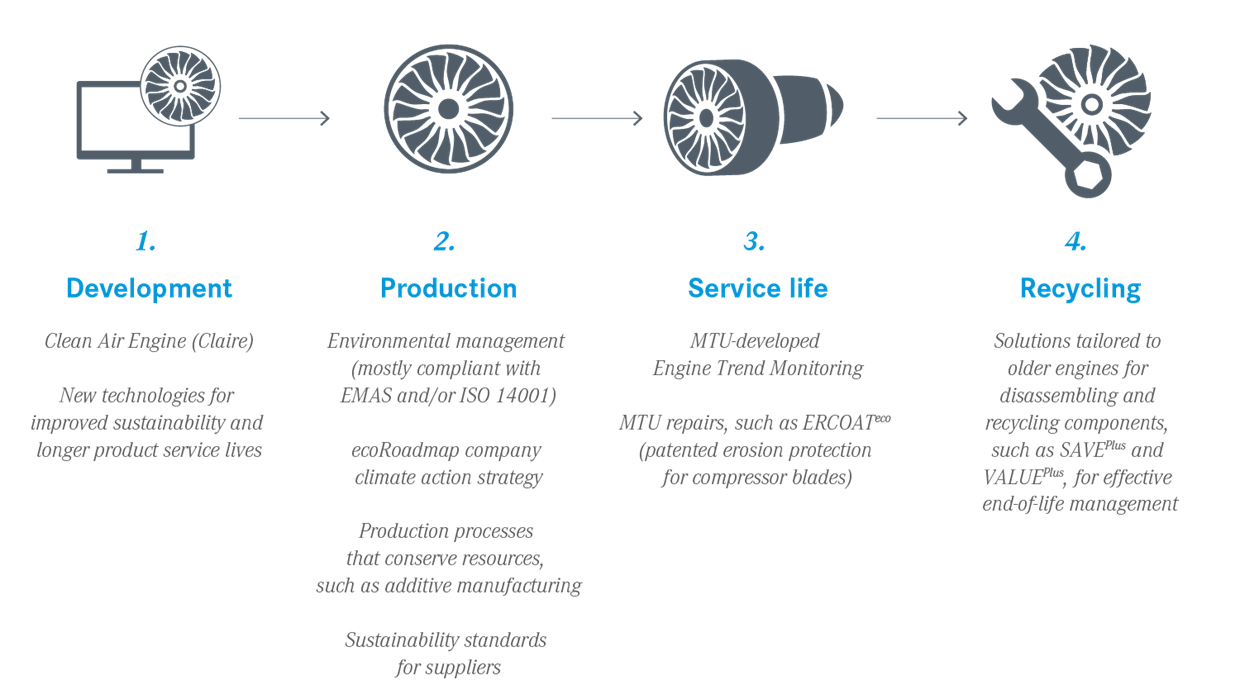

What we mean by circular economy is a lifecycle approach for our products that takes into account all phases of an engine, including the design of products and processes according to closed-loop principles. This includes the responsible use of primary resources, improved material efficiency, and the use of secondary materials without impairing the quality or safety of our products. And responsible waste management and recycling are also part of the MTU approach. In addition, we are working on extending the service life of products; and we can prevent the use of new parts by means of customized repairs in particular.

Sustainability over the lifecycle of an engine

Engine materials such as titanium, nickel, and alloying elements such as platinum or rhenium are of high value, and this explains why aircraft engines have very high recycling rates. As a vendor, we have no direct influence over the scrapping of engines, which is carried out by specialist companies.

Product development and design

In product development, designs must comply with all safety requirements and aim to create highly robust engines with a long service life. As a rule, aircraft engines spend 30 years in service before they are decommissioned. And since climate impact and energy consumption are a focus of product design, conserving resources is an integral part of the products’ lifecycle. In addition, designs ensure that the product can undergo multiple repairs throughout its service life, as repairing existing parts conserves more energy and resources than fitting new ones. At the end of an engine’s lifecycle, the metallic properties of all its constituent materials (e.g. titanium, nickel) means that they are almost entirely recyclable.

Use of materials in production and maintenance

The long service life of our products and the continuous improvement of our maintenance processes ensure our demand for raw materials is reduced. In all of our production methods, we pay attention to efficiency in the use of materials and seek to avoid waste. We develop our own production and repair methods that are characterized by their high material efficiency. The use of new repair techniques and targeted maintenance programs increases the service life of engines.

Circular economy: The example of valuable titanium chips

By returning chips from alloys to the supply chain, we are building a sustainable path to supply security, doing our bit to handle resources carefully, and reducing CO2 emissions by using recycled materials in the value creation process.

We achieve greater material efficiency in the production of new parts through the use of additive processes such as the 3D printing of metals. This manufacturing technology enables the rapid 3D production of highly complex components and allows for more freedom in designing them. Components are laser-melted directly from a powder bed according to CAD data—with just 5–10% of the powder ending up as excess material that cannot be used. We plan to employ this particularly resource-conserving method more and more as time goes on.

Our area of expertise: Engine repairs

With its “repair beats replacement” philosophy, MTU Maintenance achieves a truly impressive depth in aircraft engine repair. Using special techniques we have developed in-house, we repair engine components that in other maintenance shops would have to be replaced with new parts. For example, we manage to give around 70% of all engine blades a second, third, or even fourth lease on life. We are gradually expanding this product recycling approach to include new processes with an eye to achieving even longer service lives and thus greater material efficiency. For instance, in the case of life-limited parts, we have succeeded in repairing integrally manufactured engine blades and disks, known as “blisks.” This is important because the number of blisks being installed in engines is increasing. MTU is one of the world’s leading companies in the field of blisk production and repair. On top of that, efficient and eco-friendly processes are used for repairs. One example is the use of water jets to remove coatings from components, which avoids the need for environmentally harmful chemical processes.

In addition, we offer repairs and various other measures to improve the operating behavior of components and engines. Special coatings in particular are able to increase the performance capability and durability of components, while targeted individual repairs of components can also help lower engine emissions and improve operating behavior.

Repairs to engine components not only avoid the energy- and resource-intensive manufacture of spare parts, but also offer further opportunities in the context of the circular economy for the usage and recycling phase—for example, through the targeted use of customized repair scopes, components can be repaired not just once but multiple times.

We collect all metal parts and components for targeted recycling, especially the highly valuable materials nickel, titanium and rhenium.

Material consumption in 2023

Our material consumption mostly occurs in production. The value our facilities add depends on production materials (alloys, spray powder) as well as on consumables and supplies. In 2023, our total material consumption amounted to 9,600 metric tons, about 11% of which came from renewable materials.

|

Material consumption (in metric tons) GRI 301-1 |

|||

|

|

2023 |

2022 |

2021 |

|

Total |

9,600 |

8,740 |

8,230 |

|

Production material |

4,440 |

3,690 |

2,840 |

|

Consumables and supplies |

4,090 |

4,200 |

3,770 |

|

Other materials (renewable) |

1,070 |

850 |

1,620 |

Externally sourced material for production sites; production material comprises titanium and nickel alloys and spray powder; consumables and supplies include oils, cooling lubricants, chemicals, lubricants, gases and kerosene and diesel used as fuel; the other material comprises paper, cardboard packaging and wooden pallets and boxes. For engine parts, MTU uses returnable packaging that can be reused several times.

Our products require the use of materials that are classified as conflict minerals due to their possible origin in Central Africa and can be problematic with regard to human rights violations. As we do not procure these mineral raw materials directly, we have implemented appropriate processes in our supplier management in order to comply with our due diligence obligations for the protection of human rights. → For more information about this and how MTU is implementing Germany’s Act on Corporate Due Diligence Obligations in Supply Chains, see Human rights in the supply chain

Chemicals according to the REACh regulation

Wherever possible, we avoid using materials that are hazardous to the environment or to human health in our manufacturing processes and products. According to the European REACh (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulation, certain substances of very high concern (SVHCs) containing chromium(VI) are subject to authorization. We implement all provisions of the EU regulation for protecting employees and the environment. Our use of REACh-listed materials includes chromium trioxide for wear and corrosion protection at the Munich site. The European Chemicals Agency ECHA authorized MTU to continue its use in several of our processes until 2029 on the basis of the extremely safe workplace standards in our surface coating activities. We have applied to extend the permit for 2024.

At the same time, we are pushing ahead with the long-term elimination of SVHCs that require authorization. Through technology projects, we are searching for substitutes for chromic acid / chromium(VI). We oblige our suppliers to comply with the EU’s legal requirements (registration, authorization, etc.) via our General Terms and Conditions of Purchase if they use REACh substances in their auxiliary or operating materials.

Our waste management

MTU practices sustainable waste management with the safe disposal of waste sorted according to waste type and recycling process. First and foremost, we try to avoid waste, reuse leftover materials, and use waste either for its materials or as energy; if recycling is not possible, waste is disposed of properly. In this way, we seek to minimize material consumption and waste disposal volumes so we can achieve high recycling rates.

Back into circulation

Once again in 2023, we were able to recycle the majority of our waste

Total waste generation in 2023 rose slightly to 8,320 metric tons due to capacity utilization (2022: 7,950). The proportion of hazardous waste was 43.1% (2022: 43%). Measured against that total, the MTU Group achieved an overall recycling rate of 72.7%. The amount of waste produced and of recyclables utilized depend primarily on production capacity utilization.

|

Waste footprint (in metric tons) GRI 306-3, 306-4, 306-5 |

|||

|

|

2023 |

2022 |

2021 |

|

Total waste |

8,320 |

7,950 |

6,800 |

|

Recycled |

6,050 |

5,680 |

5,310 |

|

Disposed of |

2,270 |

2,270 |

1,490 |

|

Share of hazardous waste |

3,590 |

3,420 |

2,760 |

|

Recycled |

1,490 |

1,300 |

1,380 |

|

Disposed of |

2,100 |

2,120 |

1,380 |

Excludes construction; no data for the new site in Serbia.